Bed Of Nails Board Testing

Testing a board takes about 50 seconds of which over 40 seconds are for uploading the firmware and verifying the upload.

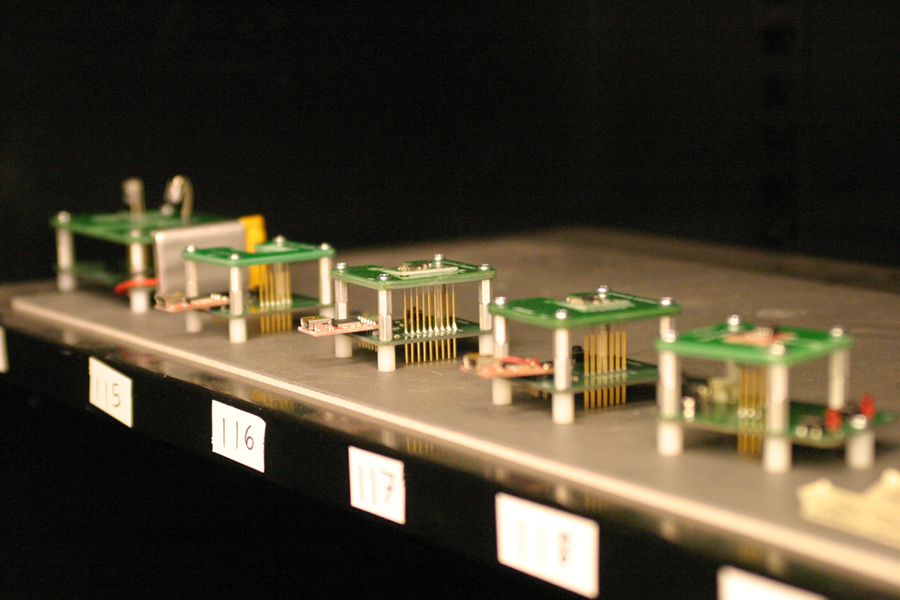

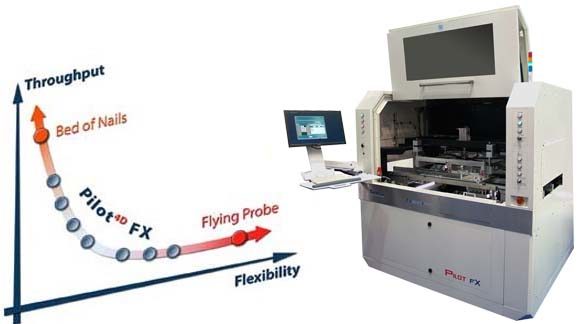

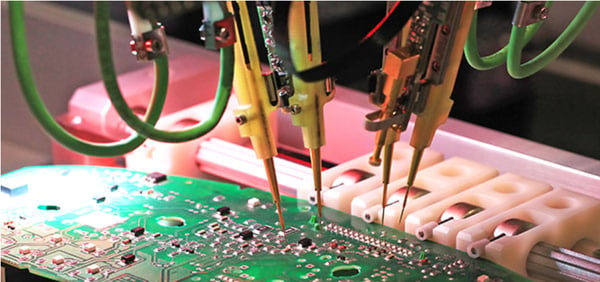

Bed of nails board testing. A bed of nails tester is a traditional electronic test fixture which has numerous pins inserted into holes in an epoxy phenolic glass cloth laminated sheet g 10 which are aligned using tooling pins to make contact with test points on a printed circuit board and are also connected to a measuring unit by wires. The test bed looks like a bed of nails as well hence the name. It only takes a few seconds to switch boards so this is a very fast and useful method especially when the manufacturer already needs to upload their own firmware to the board add 30 seconds per board and you make sure there are no defects that can cause the customer some frustration and you avoid returns. The nice thing about ict is that the 85 90 you get is totally free of human error.

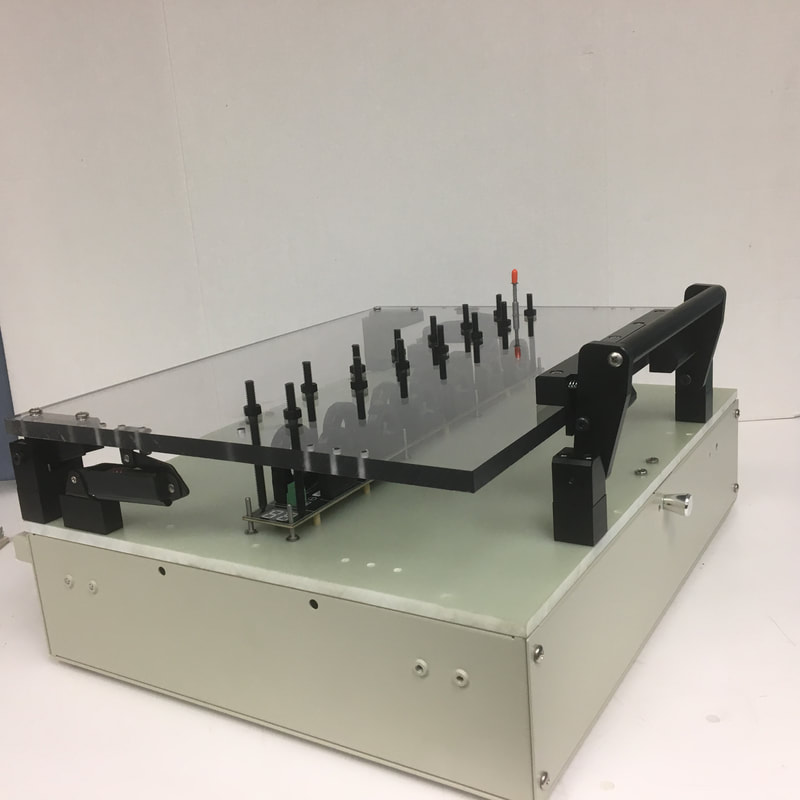

The unit will also optically read leds and key segments off lcd displays. Side access electrically probes outside panel connectors. Pneumatic style bed of nails test fixtures for high volume printed circuit board testing. The term bed of nails is a rather graphic description of what many fixtures look like having a large number of test points or probes proud of a board that holds them in place.

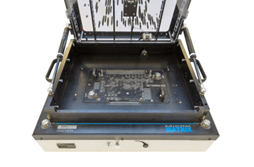

Mechanically or electrically actuated options. Specifically looking for what kinds of materials work best how to trace the board properly to make the holes in the right place in other words it s the little things that experienced people know but for a beginner would be a lifesaver. Test fixtures pneumatic test fixtures manual test fixtures vacuum test fixtures bed of nails test fixtures bed of nails testers circuit board test fixtures. 6 sided bed of nails circuit board test fixture.

Dc motors are used to adjust multiple turn potentiometers. It takes longer to build and cost more as numerous probes are required to cover the full surface of the delivery panel. Once the fixture is ready to go the fabricated pcbs are pressed down one by one onto the test pins which check for electrical conductivity and compare the results to the project s netlist file. Although the concept of the in circuit test fixture or bed of nails is broadly the same whatever manufacturer is used there are a number of variations on the basic theme.

The bed of nails test method gets its name from these protruding pins. There are other ways of testing pcbs after production too but if your board doesn t involve any type of processing they might be. Solenoids will press buttons and servos will turn selector switches. An ict also known as a bed of nails test powers up and actuates the individual circuitry on the board.

Central camming mechanism pull plates inward. Test electronics manufacturers of. When testing a complete circuit board a bed of nails can significantly reduce time and errors. What are some techniques for making a diy bed of nails.

As per the name suggests the bed of nails is a surface on which multiple test probes are positioned in order to test all signals of the pcb panel in one single operation. The fixture contains a multitude of small spring loaded test pins that protrude from a wide base that can secure the pcb. Designed primarily for testing products in plastics. The first step in bed of nails testing is to design and build a test fixture for your specific pcb design.