Bed Of Nails Pcb Assembly Tester

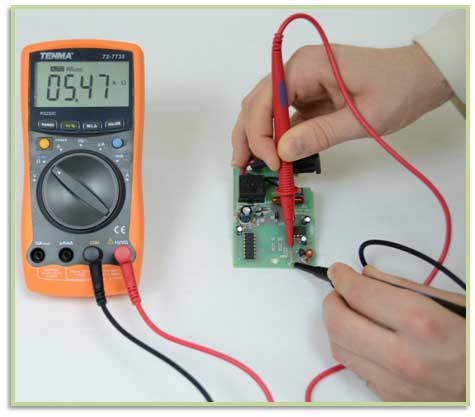

Mda testing is normally performed after automated optical inspection aoi and final visual inspection is complete.

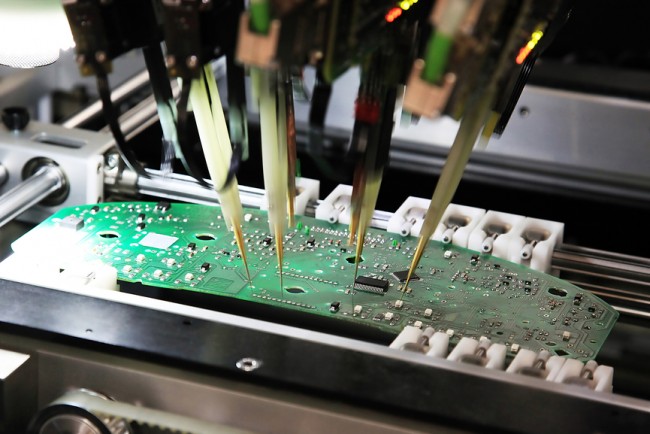

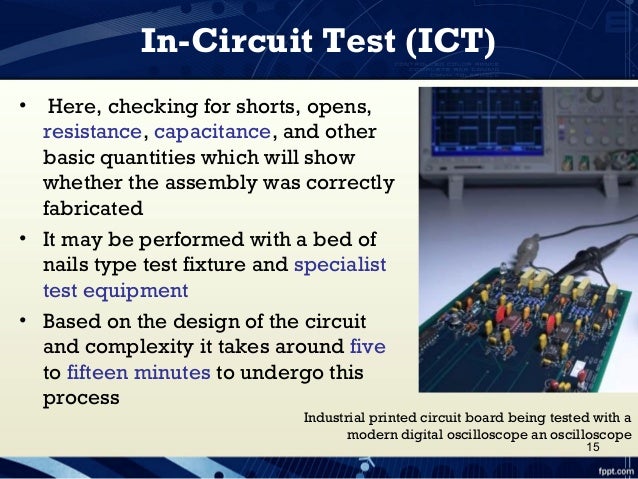

Bed of nails pcb assembly tester. The nice thing about ict is that the 85 90 you get is totally free of human. The most popular method for in circuit testing is the use of a bed of nails fixture. Fixtures with springs are connected to each test point on each circuit board. There are other ways of testing pcbs after production too but if your board doesn t involve any type of processing they might be.

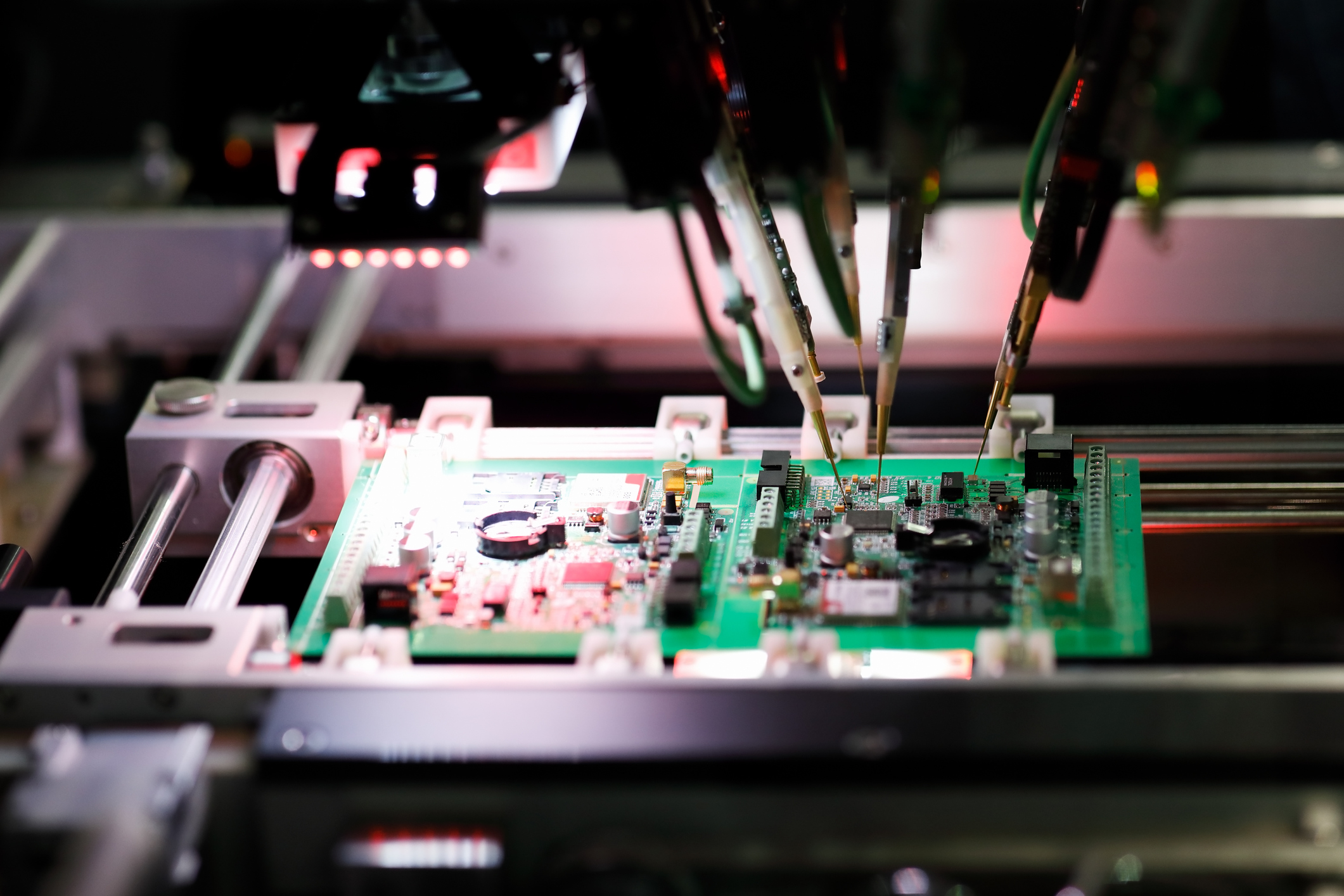

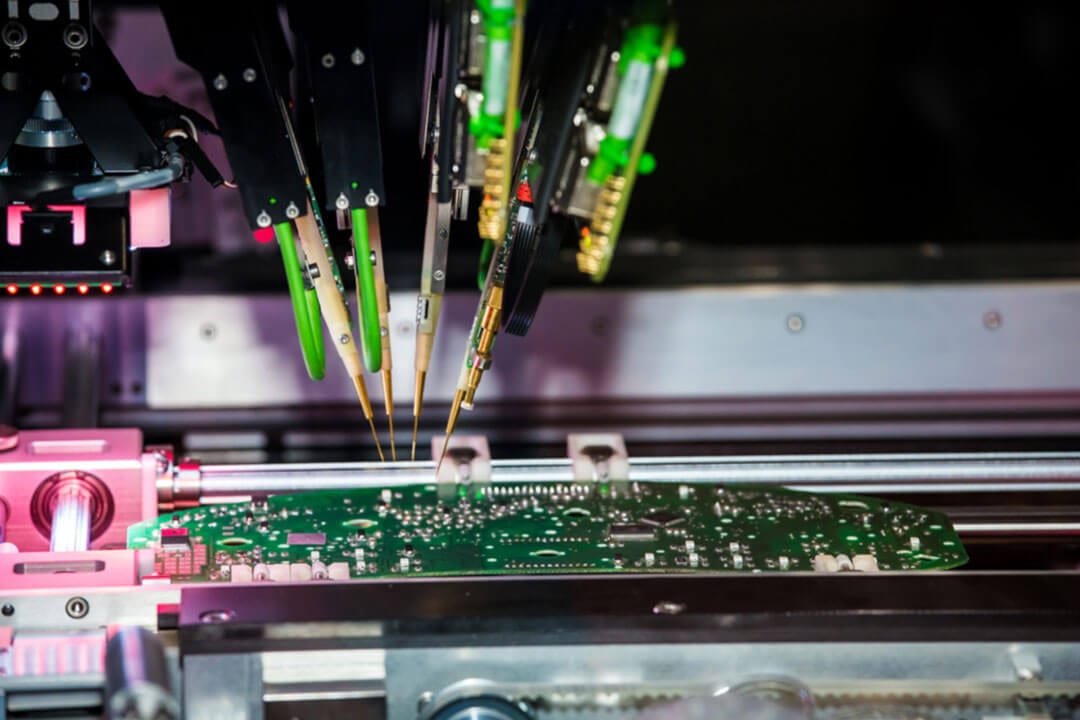

Test electronics manufacturers of. Vacuum fixtures give better signal reading versus the press down type. The bed of nails test method gets its name from these protruding pins. Such fixtures that are arranged in a matrix manifest themselves as a bed of nails.

An ict also known as a bed of nails test powers up and actuates the individual circuitry on the board. Although the concept of the in circuit test fixture or bed of nails is broadly the same whatever manufacturer is used there are a number of variations on the basic theme. The fixture contains a multitude of small spring loaded test pins that protrude from a wide base that can secure the pcb. Small dimples from the sharp tips of the pogo pins can often be seen on many of the soldered connections of the pcb.

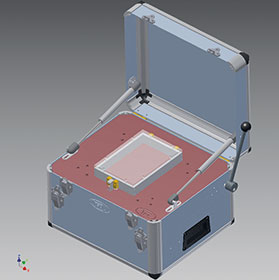

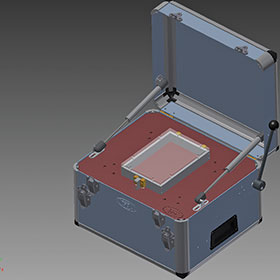

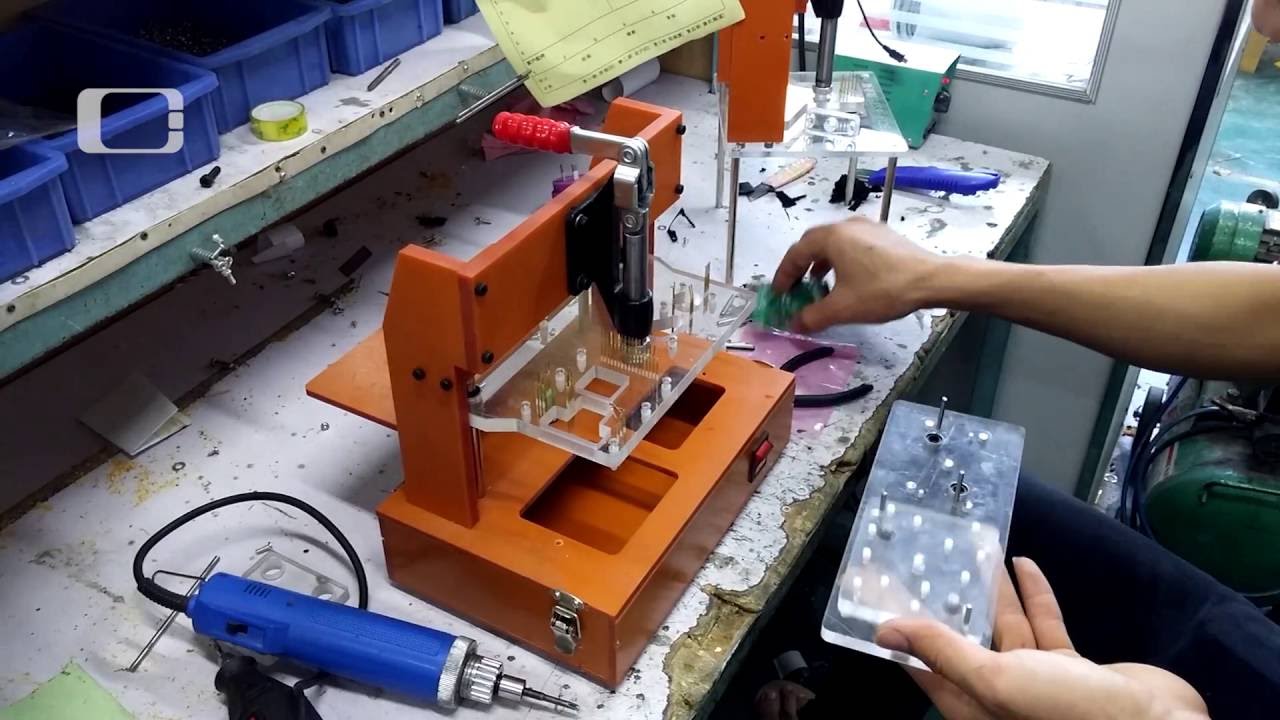

Test fixtures pneumatic test fixtures manual test fixtures vacuum test fixtures bed of nails test fixtures bed of nails testers circuit board test fixtures custom test fixtures automated test equipment mda functional testers in circuit testers clamshell test fixtures wave. Bed of nails fixtures require a mechanical assembly to hold the pcb in place. Bed of nails fixture test also called a calm shell or universal grid is implemented through dozens of stiff testing fixtures just like what its name is described. In most cases the test is designed for 100 coverage but you ll get closer to 85 90 coverage.

Controlled by test software programming should. The test bed looks like a bed of nails as well hence the name. The high price reflects that tens of thousands of dollars though the cost will depend on board and fixture size among other factors. If you are manufacturing a lot of pcbs printed circuit board you will want to have some sort of qa to ensure your boards are functional and without defects.

In circuit testing ict is the most robust type of pcb testing in existence. Fixtures can hold the pcb with either a vacuum or pressing down from the top of the pcb. Once the fixture is ready to go the fabricated pcbs are pressed down one by one onto the test pins which check for electrical conductivity and compare the results to the project s netlist file. The term bed of nails is a rather graphic description of what many fixtures look like having a large number of test points or probes proud of a board that holds them in place.

The first step in bed of nails testing is to design and build a test fixture for your specific pcb design. How to build a custom bed of nails tester for your 3d printer electronics. Springs are capable of equipping each test point with pressure of 100g to 200g to ensure excellent contact of test points.